How to Maintain Your 3D Printer for Optimal Performance (No More Failed Prints!)

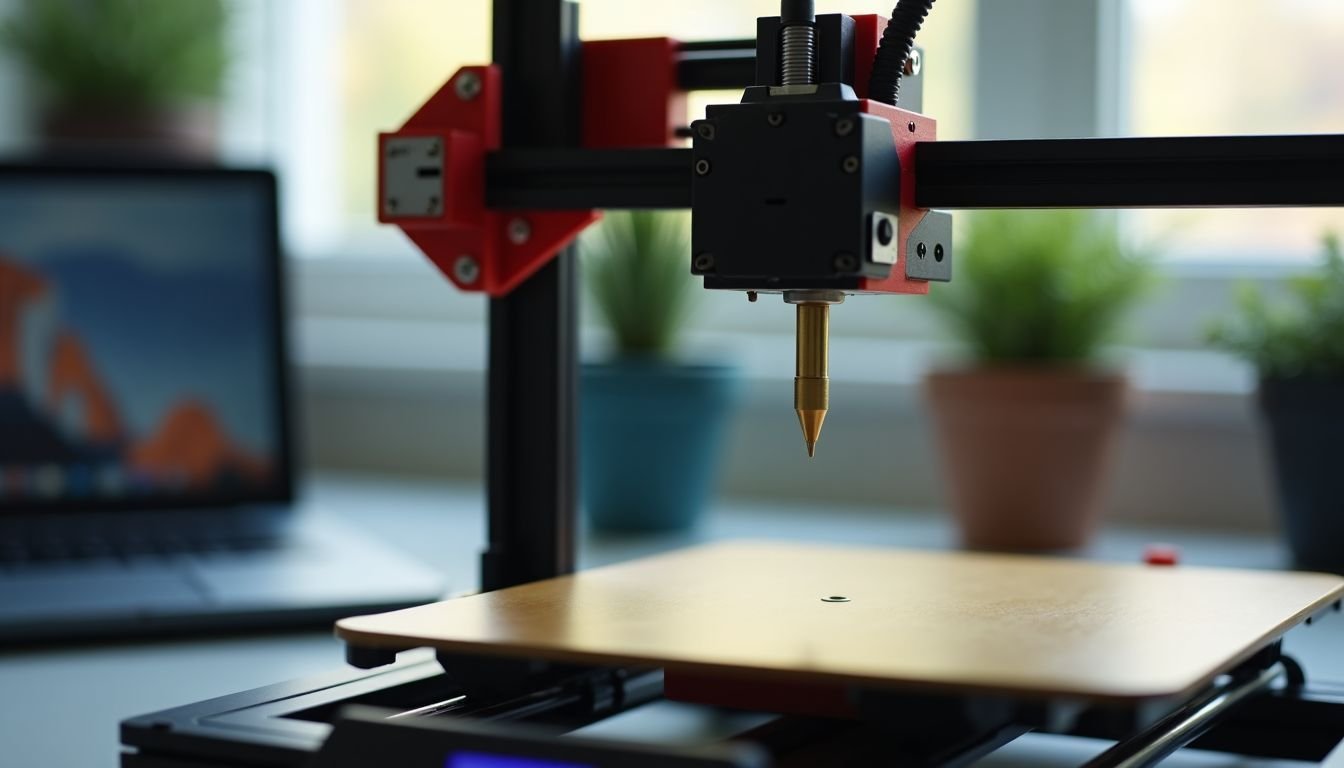

Are you tired of failed prints from your 3D printer? Proper maintenance can boost print quality and the life of your machine. This article will show you how to keep your 3D printer in top shape, tackling everything from cleaning to troubleshooting prints.

Let’s get started!

Key Takeaways

- Regular maintenance, like cleaning and lubricating moving parts, prevents wear and keeps your 3D printer running smoothly.

- Managing resin properly and storing it in a cool, dark place extends its life and ensures high-quality prints.

- Checking belt tension is crucial for accurate prints. Adjust the tension according to the manufacturer’s guidelines to prevent print defects.

- Clearing dust and debris from your printer helps avoid common printing issues such as clogged nozzles or overheated components.

- Quick troubleshooting of problems like uneven layers or a non-starting printer can save time and improve print success rates.

Why 3D Printer Maintenance is Crucial

3D printer maintenance stops failed prints before they start. Regular care keeps your printer running well and helps you create quality designs every time.

3D printer maintenance stops failed prints before they start. Regular care keeps your printer running well and helps you create quality designs every time.

Preventing failed prints

Maintaining your 3D printer helps to prevent failed prints. Regular cleaning and lubrication of moving parts ensure smooth operation. Dust and debris can lead to issues, so clear your printer often.

Check the print bed adhesion frequently. Properly stored resin avoids problems related to curing and quality.

Monitoring temperature settings is key for successful prints too. Incorrect temperatures can result in poor layer adhesion or warped parts. Keeping belts tightened also supports consistent movement during printing.

Addressing these factors keeps your projects on track.

Extending the lifespan of your printerA well-maintained printer works like a charm.

Adjusting belt tension keeps your printer running smoothly, reducing strain on the hardware.

Properly managing resin also plays a big role in longevity. Store it correctly to avoid contamination or spoilage. Make sure print settings match the material you’re using. This careful attention ensures high-quality prints while protecting your investment in D printing technology.

Ensuring high-quality prints

Maintaining your printer helps ensure high-quality prints. Clean the nozzle regularly to avoid clogs. A clogged nozzle can lead to uneven layers and poor adhesion. Check print temperature and exposure times as well.

Adjusting these settings can significantly improve print quality.

Inspect hardware often for wear and tear. Loose parts may disrupt the printing process, causing defects in your models. Keep your work area clean by clearing dust and debris from your printer.

This simple step helps maintain optimal performance during every print job.

Essential Tips for 3D Printer Maintenance

To keep your 3D printer in top shape, regularly clean and lubricate all moving parts. Check the belt tension to ensure accurate prints and prevent wear over time.

Cleaning and lubricating moving parts

Cleaning and lubricating moving parts keeps your 3D printer in great shape. Regular maintenance helps prevent print defects and ensures high-quality results.

- Dust off the printer regularly. Use a soft cloth or brush to eliminate dust from all surfaces.

- Check belts and pulleys for wear. Any damage can lead to uneven layers in your prints.

- Use a clean, dry lubricant on moving components. This action reduces friction, ensuring smooth movements.

- Inspect the rails for debris. Clear any build-up that may hinder movement for optimal performance.

- Apply a small amount of oil to bearings and sliding parts. Lubrication extends the lifespan of these critical components.

- Clean the nozzle frequently. Blockages can result in failed prints due to poor filament flow.

- Keep the print bed free of residue. A clean surface enhances print adhesion, minimizing errors during printing.

- Maintain an organized workspace. Proper storage of tools and materials prevents accidental damage to your printer.

Checking and adjusting belt tensionProper belt tension plays a crucial role in your 3D printer’s performance. A well-tensioned belt ensures accurate movement and reduces print defects.

- Examine the belts regularly for wear and tear. Look for fraying or signs of damage that might affect performance.

- Adjust the tension using the manufacturer’s guidelines. Each printer model may have specific steps to follow.

- Tighten loose belts. Ensure the belts feel firm but not overly tight, which can cause strain on motors.

- Check the pulley alignment. Misaligned pulleys can lead to uneven tension and inconsistent layer height.

- Lubricate areas around pulleys. This helps reduce friction and maintains smooth operation during each print.

- Monitor print quality closely after adjustments. Notice if there are improvements in adhesion or reduction in defects.

- Recheck belt tension pehttps://darrelaffiliate.com/wp-content/uploads/2024/12/vintage-electrical-and-electronic-appliances-in-an-2023-11-27-05-10-10-utc-e1734923695564.jpgdically, especially after significant prints or if you change filament types.

Taking these steps will help maintain optimal performance of your 3D printer. Next up, troubleshoot common 3D printer issues that may arise during use.

Properly storing and managing resin

Store your resin in a cool and dark place. Avoid direct sunlight to keep the resin fresh. Use airtight containers to prevent exposure to air, which can degrade quality. Label your containers with dates and types of resin for easy identification.

Managing leftover resin is essential too. Pour any unused liquid back into the container immediately after printing. Always wear gloves when handling resin to protect your skin from irritation.

Clean up spills promptly using appropriate materials like paper towels or cloths. First-hand experience shows that these practices can significantly improve print adhesion while preventing common D print defects.

Clearing dust and debris

Keeping your 3D printer clean helps prevent print issues. Dust and debris can disrupt its performance.

- Use a soft brush to remove dust from the printer’s extehttps://darrelaffiliate.com/wp-content/uploads/2024/12/vintage-electrical-and-electronic-appliances-in-an-2023-11-27-05-10-10-utc-e1734923695564.jpgr. This prevents dust from building up in delicate areas.

- Wipe down surfaces with a lint-free cloth. Focus on areas where resin or filament may accumulate.

- Check the print bed for dust before starting a new project. A clean surface ensures better print adhesion and reduces failures.

- Open the printer case and gently vacuum the inside components. This helps clear out any accumulated dust without causing damage.

- Avoid using harsh chemicals that could harm the printer parts. Stick to safe cleaning solutions for optimal maintenance.

- Inspect fans and vents regularly for clogs or blockages. Clear them so your 3D printer can maintain proper airflow.

- Keep your printing environment as clean as possible. Reducing airborne particles decreases the likelihood of contamination during prints.

Addressing dust and debris can significantly improve performance and produce high-quality prints every time you use your 3D printer.

Troubleshooting Common 3D Printer Issues

You can solve many common problems with your printer by checking a few key areas. Uneven layers, for instance, often result from misaligned parts or improper settings.

Uneven layers

Uneven layers can ruin your 3D prints. This issue often arises from improper printer calibration or mechanical problems. Check the level of your build plate regularly. A misaligned plate leads to inconsistent layers.

Use a caliper to measure the height of each layer after printing. If they vary, adjust your print speed and temperature settings. Inspect belts for tightness and make sure they are in good condition.

Regularly cleaning the nozzle also helps maintain even flow of filament, preventing uneven surfaces in your final product. Stay proactive with maintenance to avoid these frustrating print adhesion issues!

Printer won’t turn on

A printer that won’t turn on can be frustrating. First, check the power source. Ensure the printer is plugged in and connected. Inspect the power button for any issues. Sometimes, a faulty cable or outlet could cause problems.

If everything looks fine but your printer still won’t start, check for blown fuses or tripped circuit breakers. These can disrupt your printer’s power flow. After addressing these concerns, troubleshoot further if needed.

Resolving this issue helps you avoid delays and keeps your printing projects on track. Next, let’s look at troubleshooting uneven layers in 3D printing.

Overheated and deformed parts

Overheating can lead to deformed parts in 3D printing. High temperatures cause filament or resin to soften too much. This results in loss of shape and detail during the print process.

Regularly check your printer’s temperature settings. Adjust them if necessary to avoid overheating issues.

Inspecting the components frequently helps prevent these problems. Dust buildup around fans and vents restricts airflow, leading to increased heat. Keep your printer clean by clearing dust and debris regularly.

For best results, use proper filament management techniques for improved print adhesion too.

Conclusion: Keep Your 3D Printer Running Smoothly

Your 3D printer will perform best with regular care. Address any issues promptly to enjoy a hassle-free printing experience.

Regular maintenance is keyRegular maintenance keeps your 3D printer running smoothly. Dust and debris can build up quickly. Clean and lubricate moving parts to prevent wear and tear. Fixing issues early saves time.

Adjust belt tension often for better print quality. Properly manage resin storage to avoid spoilage.

Monitoring hardware is essential too. Conduct regular inspections of printer components. Look for worn-out parts or loose connections that could cause problems. Address print errors as soon as they arise to maintain optimal performance.

Following these printer maintenance tips ensures successful printing with fewer failures, keeping your projects on track.

Stay on top of any issues

Stay vigilant about any problems with your 3D printer. Address issues like uneven layers or printer malfunctions immediately. Regular inspections can prevent bigger headaches later on.

Look for dust and debris that might affect performance, and check if the nozzle needs cleaning. Fix common D print problems as soon as they arise to maintain optimal performance.

Proper maintenance enhances print quality and keeps your projects running smoothly. Tackle troubleshooting quickly to enjoy a hassle-free printing experience. Explore essential tips next for effective upkeep of your device.

Enjoy successful 3D printing.

Addressing issues quickly boosts your chances of success. Fixing common D print problems helps you enjoy high-quality results. Regular maintenance keeps your printer in top shape. Clean the nozzle regularly to ensure proper material flow.

Properly managing resin also contributes to better prints. Use acetone wisely for failed prints instead of letting them pile up. Each step counts toward improving D print adhesion and resolving D print errors.

Keep an eye on printer hardware inspection as well, ensuring everything functions smoothly for optimal performance.

FAQs

1. How can I maintain my 3D printer for optimal performance and prevent failed prints?

Maintaining your 3D printer involves regular cleaning, lubrication, nozzle maintenance, and troubleshooting any resin printing problems.

2. What are some common 3D print issues and how do I address them?

Common issues include defects in the printed object or complete print failures. You can resolve these by optimizing your 3D printer’s performance through proper maintenance and addressing any resin or D print troubles promptly.

3. Can acetone be used for resolving failed prints?

Yes! Acetone is a useful tool for dealing with failed prints as it helps clean up residue left on the printing platform.

4. What are some tips to troubleshoot my resin 3D prints?

Regularly cleaning the nozzle of your printer, ensuring proper calibration of settings, and using high-quality materials can help in troubleshooting resin 3D prints.

5. How does regular cleaning and lubrication help in preventing D print defects?

Cleaning removes dust that could interfere with printing while lubrication ensures smooth movement of parts which reduces chances of errors hence preventing D print defects.